How we built our Industry 4.0 solution over IoT Platform

by Hema | Sep 13, 2021 | IoT Platform, MES | 0 comments

This application development story is about how we were able to build our Industry 4.0 solution, MES software over the Bevywise IoT platform.

The recent trend of Industry 4.0 is the attainment of digital transformation on the factory floor enabling real-time decision making, enhanced productivity & flexibility in the manufacturing industry. As a part of our Industry 4.0 solution, we have recently built an MES (Manufacturing Execution System), an ultimate production monitoring & management software. This exemplary production-oriented tool monitors & tracks the entire production line providing visibility & transparency (in every aspect of the production process) with complete production control. MES collects real-time data from a modern CNC machine, send it to the central server and performs analysis to make data-driven decisions & optimize production efficiency.

Why Bevywise IoT Platform?

The Internet of things (IoT) is always meant to solve sticky, physical world problems but the pathway to integrate such technology in building our applications is almost equally intricate and complex. But there are a lot of application-enabled platforms available in the market which can almost reduce your application-building complexity. In that case, using the Bevywise IoT platform as a base framework, we built our Industry 4.0 solution, MES software. This article will walk you through the paths of how the solution is built over the Bevywise IoT platform & will portray the hacks used for IoT application development.

As I said earlier, there are plenty of IoT platforms available in the market but the configuration modules Bevywise has, make it flexible for any application development and that makes it stand out from others. The complete details on these configuration modules are explained in the below sections.

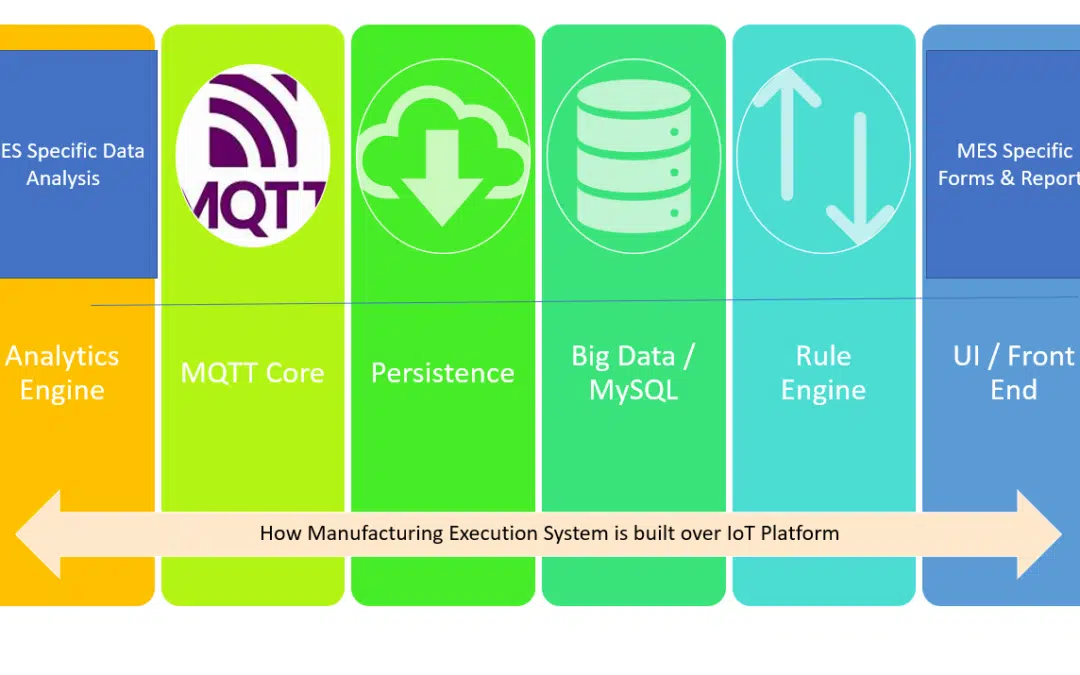

In its more sophisticated form, Bevywise IoT Platform has these modules which makes it a more powerful end-to-end IoT platform enabling developers to build faster IoT applications.

- Connectivity Layer

- Data Persister

- Databases

- User Management & Data visualization

- Action management (rules engine )

- Analytics Engine

Let us see how we were able to build MES software with these modules.

Connectivity Layer

The first & foremost need of every application development is a connectivity layer to make direct communication with the devices. In our Industry 4.0 solution, MES, we want to include connectivity as a part of the solution.

Bevywise IoT Platform with its connectivity layer brings different protocols such as MQTT, MQTT-SN & TCP into one interface, ensuring accurate data streaming and interaction with all devices. By using this connectivity layer we could establish the connectivity of Industrial machines with our application via the communication protocol. We were able to send machine data via MQTT as the Bevywise IoT platform by default supports MQTT as its communication protocol.

Data Persistence

When we create any business applications, data persistence must be enabled to persist the data object variables in the server and to prevent them from being lost between sessions. To be clear, in the context of storing data in a data store, the data survives or remains even after the process ends.

Bevywise IoT Platform has this functionality which persists the device connection entry into MySQL. However, we may also want to store the device data in other persistence layers. Hence, Bevywise supports storing device data in Elastic Search. With data persistence, the data stored in both MySQL and Elastic search is persisted to make it remain for further analysis.

This makes us get utilized with persister in our MES software. For example, some data in industrial organizations must be persistent.

That is, our MES software includes multiple fields in the setup process, that a user must complete. Also, the user is added by filling in multiple fields. The information entered in such fields should exist and with persistence enabled the information that the user enters in those fields persist.

Databases

Literally, every application probably needs a database that acts as a repository to store the necessary data sets. Coming to our Industry 4.0 solutions, we need a database to get integrated into it to store all the critical industrial information.

As said earlier, Bevywise IoT Platform supports storage of data in Elastic search. Also, the device connection will be stored in MySQL.

User Management & Data Visualization

The next fundamental element that every IoT application need is the user interface. After we collect data from machines & store it in DB, the next thing we need to do is to deliver the information to the end user/someone who is intended to proceed with the next step of the industrial process. This can be done via the user interface. This is the interface by which any industrial user communicates or interacts with the application. Also, we need to make sure that UI must visually represents the data which enables users to see patterns and observe trends from manufacturing dashboards where data is vividly portrayed through charts & graphs. And you know what?? Our IoT platform makes it much easier for us as it supports custom dashboard functionality which permits the creation of multiple dashboards with 10+ pre-built widgets specific to any application. We were able to lay out OEE metrics and other machine data in charts & graphs.

Further, the manufacturing industry will have multiple departments and each department will be handled by a certain set of users. It is not always right to provide each & every access to all the users in the industry. Thus, it is necessary to manage each user by providing specific roles & permissions. In that case, the Bevywise IoT platform empowers the service provider to administator & supervise multiple users & their access to and from various sectors. With its multi-tenancy architecture, employees can be given individual web access and login & can be provided with separate roles & permissions for each to carry out machine management & monitoring tasks.

Action Management

The next key function is to bring data to life with rule-based event-action-triggers enabling the execution of “smart” actions based on specific machine data. This is more like automating some actions based on the condition we set. For instance, alerting the production manager when a machine sits idle.

This is executed with a powerful condition-based rule engine of the IoT platform which helps the user to forward alert messages to the subscriber.

How we built MES over the platform

The scalability, flexibility & end-to-end application framework of the IoT platform enables us to build MES software without touching the core side. We have used these modules to configure and develop our MES solution specific to the need.

In addition to these, we have made some changes to the analytic engine of the platform and in front-end modules to develop the perfect MES solution for the manufacturers.

Analytic Engine

Every manufacturing industry now expects advanced analytics such as predictive analysis to foresee developments and respond to challenges & machine failures proactively. But this requires advanced techniques such as machine learning & artificial intelligence which need aggregated data from machines to anticipate more accurately.

This is where the analytics engine of the Bevywise platform comes in. The analytic engine collects data stored in Elastic Search & aggregates it as needed. It executes data aggregation to summarize every 5 mins data and stores it. Then the data will be displayed in reports as per the needs of users. The analytic engine of the IoT platform is purely based on devices.

We have made a few changes to it as we want to make this analytic engine work based on, the production plan, shift & production process. For instance, MES software needs to display day, shift, monthly & yearly data in the form of reports. This requires data to be aggregated for every, day, month & year. A few changes in the analytic engine have been done to execute such aggregation. Now, MES software will be able to provide shift, day, month & year-wise production reports.

User Interface module

Manufacturing Industry requires data to be presented as an OEE metric with other key performance indicators such as availability, performance & quality in a way to assist the manufacturers to come up with actionable insights. As our MES software tracks multiple machines & departments, the data should also be displayed machine-wise, unit-wise, and department-wise OEE. The comparison of the production plan set & the actual production target reached also needs to be displayed. Hence, the UI module has been configured to make these components available to the manufacturers in the visual form of the user interface itself. Thus we were able to develop our MES over the Bevywise IoT platform faster & much easier breaking down all the application development complexities.

We have a trial set up of device manager for trying the IoT platform for FREE. You can connect your devices & start with your implementation/application development. Contact our team now to get our IoT Platform.